Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 15:01:51

Visit:

Forging is a metal plastic forming process that applies external force to cause plastic deformation of metal materials in the solid state, thereby changing their shape, size, and improving their internal structure. The forging process is usually carried out above or below the recrystallization temperature of the metal material, depending on the specific forging type, such as hot forging, warm forging, or cold forging. During the forging process, metal material is placed on a mold or anvil, and then subjected to impact or pressure using forging hammers, presses, and other equipment to promote metal flow and fill the shape of the mold.

The main difference between forging, casting, and machining lies in the processing principle and the characteristics of the final product.

Casting is a process of melting metal into a liquid state, pouring it into a pre prepared mold, and taking out the finished product after it cools and solidifies. Casting is suitable for producing complex shaped parts, especially those structures that are difficult to achieve through forging or machining. The material for casting can be almost any metal, from aluminum and copper to steel and precious metals. However, the mechanical properties of cast parts are usually inferior to forged parts, as porosity, shrinkage, and other defects may form during the casting process.

Machining is the process of removing material through cutting tools to achieve the desired shape and size, including turning, milling, drilling, grinding, and other techniques. Machining can provide high precision and surface smoothness, suitable for parts with strict requirements for dimensional tolerances and surface quality. However, machining is usually costly as it involves material waste (i.e. chips) and longer processing times.

In contrast, forging can effectively improve the microstructure of metal materials and enhance their mechanical properties, such as strength, toughness, and fatigue life. The plastic deformation during the forging process can refine the grain size of the metal, remove defects such as porosity and looseness during the casting process, and optimize the streamline direction of the material to make it more suitable for bearing working loads. In addition, forged parts usually have higher dimensional stability and strength to weight ratio, which makes forging processing very important in industries such as aerospace, automotive, energy, and heavy machinery.

In summary, forging, casting, and machining each have their unique advantages and applicability. The choice of machining method depends on the complexity of the required part shape, performance requirements, production batch size, and cost considerations.

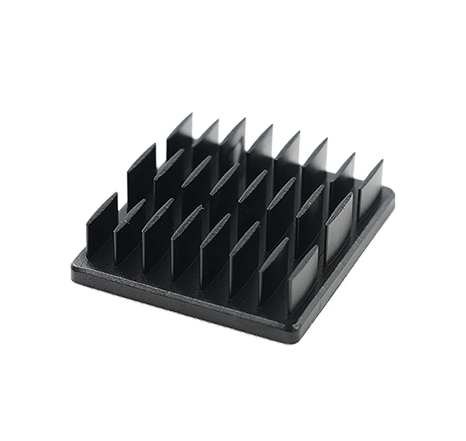

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network