Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 15:00:44

Visit:

Forging is a processing method that uses external forces to cause plastic deformation of metal materials, thereby changing their geometric shape and improving their internal structure. According to the temperature state of metal materials during processing, forging can be divided into three main types: hot forging, warm forging, and cold forging.

Hot forging is a forging process carried out above the recrystallization temperature of metal materials, during which the metal material is in a red hot state, with high plasticity and low deformation resistance. Hot forging is usually carried out between 800 ° C and 1200 ° C, depending on the type of metal. Within this temperature range, the flow stress of metal materials decreases, making it easier to form complex shapes and avoid work hardening, reducing the risk of cracking. Hot forging can achieve good organizational structure and mechanical properties, but due to high-temperature operation, there are certain safety hazards such as fire, explosion, and burn risks.

Warm forging is a forging process that is carried out below the recrystallization temperature of the metal, but still above room temperature. The temperature range for warm forging is approximately between 400 ° C and 700 ° C, depending on the type of metal. This forging method combines some advantages of cold forging and hot forging, which can achieve good dimensional accuracy and surface quality. At the same time, due to the influence of temperature, the plasticity of the material is improved, reducing deformation resistance. Warm forging has advantages in improving material utilization, reducing subsequent processing volume, and enhancing material properties.

Cold forging is a forging process carried out at or near room temperature. Cold forging requires materials to have sufficient plasticity and is commonly used for low-alloy steels, copper alloys, and aluminum alloys. Due to the absence of heating process, cold forging can maintain the original surface smoothness of the material, with high dimensional accuracy and good surface quality. However, cold forging has higher requirements for materials and requires greater deformation force, thus placing higher demands on the strength and rigidity of the equipment. Cold forging is suitable for producing small-sized, large-scale precision parts such as bolts, nuts, and gears.

Each forging method has its specific application scenarios and advantages and disadvantages. Choosing the appropriate forging type is crucial for ensuring product quality, controlling costs, and improving production efficiency.

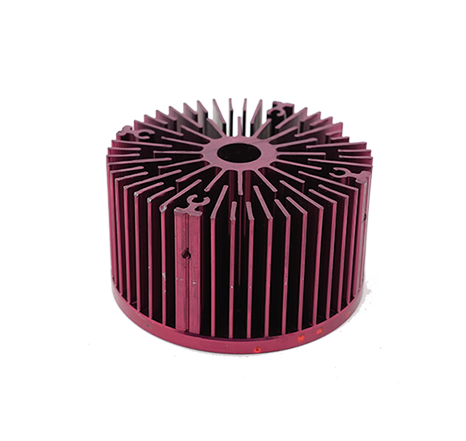

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network