Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 15:04:07

Visit:

Forging is an important metal forming technology that applies external pressure to deform the metal in a plastic state. This process not only changes the macroscopic shape of the metal, but also has a profound impact on its microstructure and mechanical properties.

Microstructure changes:

1. Grain refinement: During the forging process, the metal material is subjected to compression and shear stress, causing the original coarse grains to break and form finer grains. The fine grain structure can improve the strength and toughness of metals because an increase in the number of grain boundaries can hinder the movement of dislocations, thereby enhancing the hardness and tensile strength of materials.

2. Organizational densification: During the forging process, existing defects such as voids, pores, shrinkage cavities, and looseness are compacted, increasing the density of the material, reducing internal defects, and improving the overall density and uniformity of the material.

3. Streamline optimization: Forging rearranges the streamline in the metal along the direction of deformation, forming the so-called forging streamline. These streamlines can enhance the mechanical properties of metals along specific directions, which is particularly advantageous for components that can withstand directional loads.

Mechanical performance changes:

1. Strength and hardness improvement: Due to grain refinement and microstructure densification, forged metal materials exhibit higher tensile strength and hardness.

2. Improvement of plasticity and toughness: Although the strength and hardness are increased, appropriate forging processes can also maintain or improve the plasticity and toughness of materials, making them less prone to brittle fracture when subjected to impact and deformation.

3. Fatigue performance enhancement: Forging can effectively reduce the initial defects inside the material, thereby significantly improving the fatigue life of the metal, which is crucial for parts that can withstand cyclic loads for a long time.

4. Improvement of fracture toughness: Refined grains and optimized microstructure help to enhance the fracture toughness of materials, that is, the ability of materials to resist crack propagation.

5. Enhanced stress corrosion resistance: The dense structure formed during the forging process reduces the opportunity for corrosive media to penetrate, thereby improving the material's stress corrosion resistance.

In summary, forging significantly improves the mechanical properties of metals by altering their microstructure, making them more suitable for manufacturing high-performance components that can withstand high loads and complex working conditions. However, in order to maximize the forging effect, it is necessary to carefully design the forging process, including selecting appropriate forging temperature, speed, pressure, and mold, to ensure that the metal material obtains the best performance while forming.

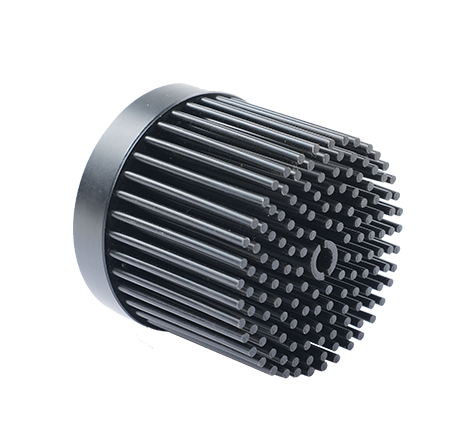

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network