Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 15:05:17

Visit:

The maintenance and upkeep of metal stamping equipment are key to ensuring its long-term stable operation and extending its service life. The correct maintenance strategy can not only improve production efficiency, but also reduce the risk of unexpected downtime and maintenance costs. The following are several key aspects to pay attention to in the maintenance and upkeep of metal stamping equipment:

1. Cleaning and anti-corrosion:

Regularly clean the inside and outside of the equipment, remove oil stains, metal debris, and other impurities to prevent the accumulation of these substances from causing equipment wear or jamming.

Cover non working surfaces of equipment with rust inhibitors or oil films, especially in environments that have been idle for a long time or have high humidity, to prevent rusting.

2. Lubrication and wear inspection:

Regularly lubricate all moving parts, such as guides, sliders, gears, and bearings, to reduce friction and extend equipment life.

Check the wear level of key components, such as molds, guide columns, guide sleeves, and springs, and replace severely worn components in a timely manner to avoid greater losses caused by component failure.

3. Electrical system inspection:

Regularly inspect circuits and electrical components to ensure secure wiring, good contact, and prevent short circuits or open circuits.

Clean the interior of the electrical cabinet, maintain ventilation, and avoid dust accumulation that may cause overheating or short circuits.

4. Maintenance of hydraulic and pneumatic systems:

Check the cleanliness of hydraulic oil and pneumatic systems, regularly replace filters, and maintain the purity of oil and gas.

Monitor hydraulic oil level and pressure to ensure stable system pressure and prevent leakage or insufficient pressure.

5. Mold maintenance:

The mold is the core of the stamping process, and its integrity and wear should be checked regularly. The surface of the mold should be cleaned in a timely manner to maintain good lubrication.

The vulnerable parts such as springs and side pins of the mold should be replaced regularly to avoid mold failure due to fatigue or damage.

6. Regular calibration and testing:

Regularly verify the accuracy of equipment using professional tools, such as parallelism, perpendicularity, and straightness, to ensure that the equipment is in optimal working condition.

Perform functional testing on the device to check if all actions are smooth and if the response is sensitive.

7. Establish and maintain records:

Record the specific operations of each maintenance, the parts replaced, and the problems discovered, in order to track the health status of the equipment and predict future maintenance needs.

By implementing these maintenance and upkeep measures, the reliability and production efficiency of metal stamping equipment can be significantly improved, while reducing production costs and downtime.

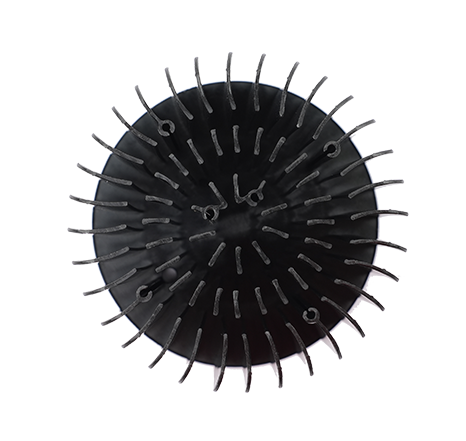

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network