Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-11-02 08:27:43

Visit:

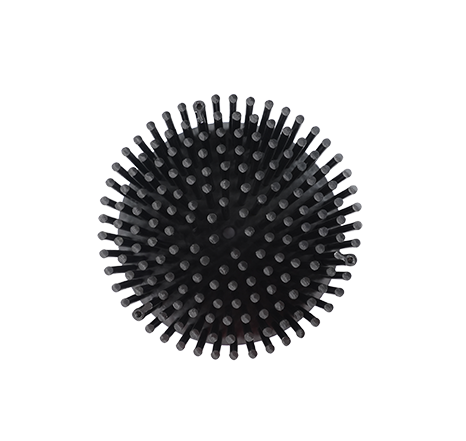

Cold forging radiator is an efficient heat dissipation device, and the selection of materials is crucial for its performance.

1、 Suitable materials

aluminium alloy

Aluminum alloy is one of the commonly used materials for cold forging heat sinks. For example, 6061 aluminum alloy contains elements such as magnesium and silicon. This alloy has good thermal conductivity, with a thermal conductivity generally between 167-201W/(m · K). At the same time, the density of aluminum alloy is relatively low, about 2.7g/cm ³, which makes the radiator lightweight while ensuring heat dissipation performance, making it easy to install and use in equipment with weight requirements.

copper alloy

Like pure copper, which has a thermal conductivity of 385-401 W/(m · K), it is an excellent thermal conductive material. In some situations where high heat dissipation is required, such as in the heat sink of high-power electronic devices. However, the density of copper is relatively high, about 8.96g/cm ³, which may result in a heavier overall weight of the radiator. For comprehensive performance, copper alloys such as brass (copper zinc alloy) are also used, which improve other properties through alloying while maintaining a certain level of thermal conductivity.

magnesium alloy

The density of magnesium alloy is lower, about 1.74-1.85g/cm ³. Although its thermal conductivity (generally between 70-156W/(m · K)) is not as good as copper and aluminum, magnesium alloy is also an optional material in some weight sensitive and low heat dissipation applications, such as portable electronic devices.

2、 Material selection criteria

Thermal conductivity

The thermal conductivity of the material is the primary consideration factor. The higher the thermal conductivity, the faster the heat is transferred inside the material, which can efficiently transfer heat from the heat source to the surface of the heat sink and then dissipate it into the surrounding environment. For example, when dealing with high-power chip heat dissipation, it is necessary to choose materials with high thermal conductivity, such as copper or high thermal conductivity aluminum alloy, to ensure that the chip will not experience performance degradation or even damage due to overheating during operation.

density

For some devices that require movement or have strict weight restrictions, such as laptops, drones, etc., the density of the heat sink material is crucial. Lighter materials can reduce the overall weight of equipment, improve its portability and energy efficiency. In this case, magnesium alloy or aluminum alloy has more advantages than copper alloy.

cost

Material cost is also an important consideration factor. Although copper has good thermal conductivity, its price is relatively high. Aluminum alloy has a lower cost, and when meeting certain heat dissipation requirements, a large number of industrial and civilian products will prioritize aluminum alloy to control costs.

Processing performance

The cold forging process requires materials to have good cold working performance. The material should be easy to form and there should be no defects such as cracks during the cold forging process. For example, some aluminum alloys can form complex heat sink fin structures and increase heat dissipation area through appropriate molds and process parameters during cold forging. At the same time, the weldability and other processing properties of materials can also affect the manufacturing and assembly of heat sinks. For example, good welding performance is important when connecting heat sinks to other components.

Corrosion resistance

Radiators may come into contact with various media in the working environment, such as moisture and chemicals in the air. The material needs to have a certain degree of corrosion resistance to ensure the service life of the radiator. For example, aluminum alloys can improve their corrosion resistance through surface treatments such as anodizing, enabling them to work stably under different environmental conditions.

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network