Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2025-05-15 15:18:34

Visit:

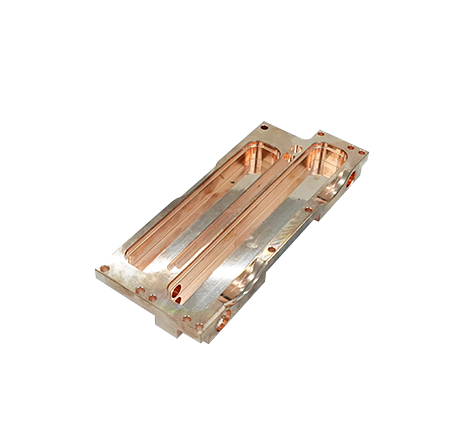

The shape of the fins is a fundamental factor affecting the heat dissipation performance. Common fin shapes include straight type, wavy type, serrated type, etc. Straight fins have a simple structure and are easy to process and manufacture. However, their contact area with air is relatively limited. When air flows on their surface, it is easy to form a boundary layer, which hinders heat transfer. In contrast, the wavy fins increase the contact area with the air through the undulating structure, causing the air to be disturbed during the flow process, breaking the boundary layer and accelerating the heat exchange rate. The serrated fins further optimize the air flow path. The sharp serrated edges can more effectively cut the air, enhance the turbulence of the air, and improve the heat dissipation efficiency. However, while complex-shaped fins enhance heat dissipation, they may also increase processing difficulty and cost, and a balance needs to be struck between performance and cost.

The size of the fins also has a significant impact on the performance of the heat sink. The height, thickness and spacing of the fins all need to be comprehensively considered. An increase in the height of the fins can increase the contact area with the air, which theoretically helps to enhance the heat dissipation capacity. However, overly large fins may cause a significant temperature difference between the bottom and the top, preventing heat from being transferred to the tip of the fins in a timely manner, which instead reduces the heat dissipation efficiency. In terms of fin thickness, overly thick fins will increase the amount of material used and weight, which is not conducive to the overall lightweight design of the radiator. Moreover, when heat is conducted inside the fins, a certain thermal resistance will be generated. Fins that are too thin may lack strength and are prone to deformation during processing and use. The setting of the fin spacing is also of vital importance. If the spacing is too small, the air flow resistance will increase, and the air will be difficult to circulate smoothly between the fins, resulting in the heat not being carried away in time. If the spacing is too large, although the air flow will be enhanced, the effective heat dissipation area will be reduced. An appropriate fin spacing can ensure air circulation while providing a large heat dissipation area, achieving effective heat dissipation.

The arrangement of the fins is also an important factor affecting the heat dissipation performance. The common arrangement methods include parallel arrangement and staggered arrangement. The fins arranged in parallel make the air flow more smoothly during the process, but it is easy to form dead zones of air flow between adjacent fins, which affects heat exchange. The interlaced fins break the regularity of air flow, causing the air to constantly change direction between the fins, increasing the contact opportunities with the fin surfaces and enhancing the heat dissipation efficiency. In practical applications, by rationally choosing the arrangement of fins based on factors such as the installation space of the equipment and the direction of air flow, the heat dissipation performance of the cold forged heat sink can be better exerted.

In addition, the surface treatment process of the fins will also have an impact on the heat dissipation performance. By treating the surface of the fins through processes such as anodizing and spraying, not only can the corrosion resistance of the fins be improved, but also the emissivity of their surface can be changed. The higher the emissivity, the more heat the fins dissipate through thermal radiation, which helps to enhance the overall heat dissipation effect. The design of the heat dissipation fins of cold forged heat sinks has a significant impact on their performance in multiple aspects, including shape, size, arrangement, and surface treatment.

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network