Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 14:48:00

Visit:

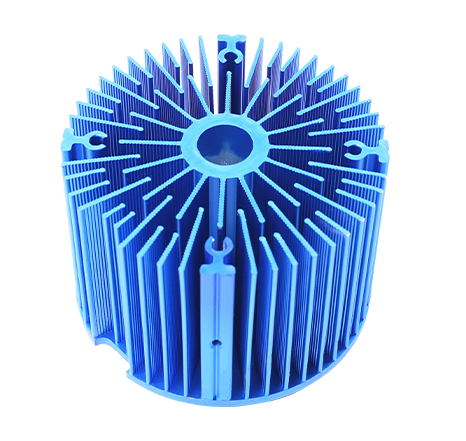

Evaluating and testing the performance of cold forged heat sinks involves multiple aspects, including thermal performance, mechanical strength, noise level, durability, and compatibility. Here are some key testing methods and evaluation metrics:

1. Thermal performance testing

Thermal performance is one of the most important attributes of a radiator. The temperature distribution on the surface of the heat sink can be detected by a thermal imaging device to evaluate its thermal conductivity efficiency. In addition, temperature sensors are used to monitor the temperature changes of the radiator under different heat source powers, and the thermal resistance (Rth) is calculated. The lower the thermal resistance, the better the heat dissipation performance.

2. Wind resistance and fluid dynamics testing

Measure the wind resistance and fluid dynamics characteristics of the radiator through wind tunnel experiments or CFD (Computational Fluid Dynamics) software simulations. Low wind resistance helps to increase air flow, thereby improving heat dissipation efficiency.

3. Mechanical strength testing

Use pressure testing and vibration testing to evaluate the mechanical strength and stability of the radiator. This includes applying static and dynamic loads, checking for material deformation or failure.

4. Noise testing

Measure the noise level generated by radiators (especially those with fans) in a quiet environment using a sound level meter. Low noise is an important indicator for measuring radiator design, especially in applications that require a quiet environment.

5. Durability testing

Evaluate the durability of the radiator under extreme conditions through cold and hot cycling tests, salt spray tests, etc. This includes repeatedly experiencing high and low temperature environments, as well as testing corrosion resistance performance.

6. Compatibility and installation testing

Check whether the radiator is compatible with the target platform or device, including physical installation testing and electrical connection testing, to ensure that the radiator can be installed correctly and work effectively.

7. Economic evaluation

Assess the overall economic benefits of the radiator by considering its initial cost, maintenance cost, and long-term operating cost. This also includes energy efficiency, which is the ratio of the electricity consumed by the radiator during operation to the cooling effect provided.

8. Material and process validation

Ensure that the materials and cold forging processes used comply with standards, and verify the consistency of material properties and processes through metallographic analysis, hardness testing, and microstructure observation.

When conducting the above tests, relevant industry standards and specifications, such as ASTM, ISO standards, etc., are usually referred to to ensure the accuracy and comparability of the test results. By comprehensively evaluating these performance indicators, we can gain a comprehensive understanding of the quality and applicability of cold forged radiators, and make informed purchasing and design decisions accordingly.

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network