Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 14:49:05

Visit:

Profile radiators and cold forging radiators are two different heat dissipation solutions under different manufacturing processes and technological paths, with differences in materials, manufacturing methods, performance characteristics, and application fields.

1. Manufacturing process

Profile heat sink: Usually using extrusion molding technology, aluminum profiles are heated to a certain temperature and then extruded into the desired shape through molds. This method can produce long, continuous heat sinks that are easy to cut into the desired length. Extrusion molding allows for the manufacture of heat sinks with complex cross-sectional shapes, such as structures with fins, but may be limited in terms of thermal conductivity.

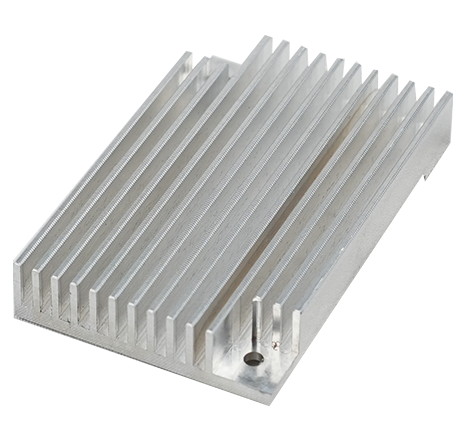

Cold forged radiator: It is a radiator shape formed by plastic deformation of metal materials under high pressure at room temperature. Cold forging technology can improve the density of materials, reduce internal defects, and thus enhance thermal conductivity. In addition, cold forging can achieve more refined structural design, such as thin walls and microchannels, to increase heat dissipation area and improve heat dissipation efficiency.

2. Material selection

Aluminum alloy, such as A6063, is commonly used for profile radiators because this material is easy to extrude and has good thermal conductivity.

Cold forged radiator: Although various materials can be selected theoretically, in practice, pure aluminum (such as AL1070) is widely used due to its high thermal conductivity and good plastic deformation ability.

3. Performance comparison

Cold forged heat sinks typically exhibit better thermal performance, partly due to the denser microstructure of the material and shorter heat conduction paths. Meanwhile, the cold forging process allows for the design of more complex internal structures, such as microchannels, thereby increasing the heat exchange area.

The advantages of profile radiators are low cost, short processing cycle, and the ability to achieve a longer continuous heat dissipation structure, making them suitable for large-scale production.

4. Application Fields

Cold forged heat sinks are particularly suitable for high-power, space limited, or high heat dissipation electronic devices such as LED lamps, high-performance computers, and servers due to their excellent heat dissipation performance.

Profile radiators are widely used in ordinary electronic products, household appliances, and general industrial equipment due to their cost-effectiveness and processing flexibility.

5. Cost and Production

The initial mold cost for cold forging radiators may be higher, but due to their effective heat dissipation performance, the unit cost may be lower for mass production.

Profile radiators may have an advantage in single piece cost, especially when extreme heat dissipation performance is not required.

In summary, the choice between profile radiators or cold forged radiators depends on specific application requirements, including heat dissipation efficiency, cost budget, production scale, and design complexity.

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network