Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 14:47:01

Visit:

The development trend of future cold forging radiator technology will revolve around advances in materials science, innovation in manufacturing processes, and the pursuit of higher performance and sustainability. Here are several key development directions:

1. Development of new materials and alloys

With the advancement of nanotechnology and alloy design, future cold forging heat sinks will adopt new alloy materials that may have higher thermal conductivity, better processing performance, and lighter weight. For example, researchers are exploring the use of graphene reinforced composite materials and customized alloy formulations to further enhance the performance of heat sinks.

2. Micro nano scale structural design

Cold forging technology will be combined with micro nano manufacturing technology to develop heat sinks with complex microstructures, such as microchannels and nanoscale heat dissipation fins. These micro nano structures can significantly increase the heat dissipation surface area, improve fluid dynamics characteristics, and thus significantly enhance heat dissipation efficiency.

3. Digitization and Intelligent Design

By utilizing artificial intelligence and big data analysis, the design of heat sinks will be more accurate and personalized. Numerical simulation technology will help engineers optimize the shape and size of heat sinks during the design phase, ensuring optimal thermal management in practical applications.

4. Green Manufacturing and Circular Economy

Sustainability will become an important driving force for the development of cold forging radiator technology. By improving the cold forging process, reducing material waste, improving energy efficiency, and using recyclable materials, the production of radiators will be more environmentally friendly. In addition, designing detachable and upgradable heat dissipation modules will also promote the development of circular economy.

5. Adaptive and intelligent heat dissipation

Future radiators will have adaptive capabilities and be able to automatically adjust their cooling strategies based on environmental temperature and load conditions. The heat sink with integrated sensors and intelligent control system will be able to monitor and adjust the heat dissipation performance in real time, ensuring that electronic devices operate at their optimal state.

6. Highly integrated thermal management solution

Cold forged heat sinks will be more tightly integrated with other thermal management components such as heat pipes, phase change materials, etc., forming an integrated thermal management system. This integrated design not only simplifies the assembly process, but also provides more comprehensive thermal management functions.

7. Customization and on-demand manufacturing

With the advancement of 3D printing and additive manufacturing technology, cold forging heat sinks will be able to achieve customized production on demand, meeting the special needs of specific applications such as space constraints, shape complexity, or specific thermal performance requirements.

In summary, the future development of cold forging radiator technology will focus on improving performance, optimizing design, enhancing intelligence, and promoting sustainability to adapt to constantly changing market demands and technological challenges.

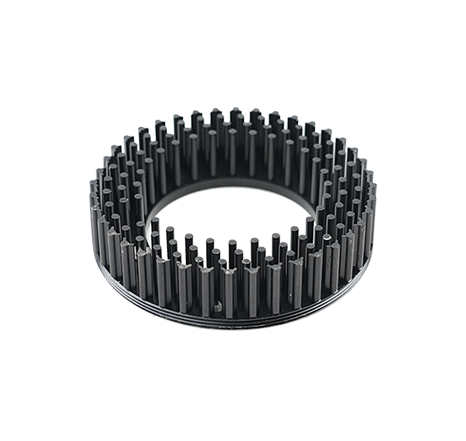

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network