Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 14:57:35

Visit:

Faced with the industry trends of green manufacturing and intelligent heat dissipation, radiator manufacturers have taken a series of measures to adapt to these changes, ensuring that their products are not only effective but also environmentally friendly, while also incorporating intelligent features. Here are some key strategies for radiator manufacturers to address these trends:

1. Green materials and sustainable production

Manufacturers are beginning to lean towards using renewable or recyclable materials, such as recycled aluminum and bio based plastics, to manufacture heat sinks and reduce their impact on the environment. At the same time, optimize production processes, reduce energy consumption, implement energy-saving and emission reduction measures, such as using solar power, improving equipment efficiency, and recycling water resources.

2. Effective energy-saving design

In order to improve energy efficiency, manufacturers consider thermodynamic and fluid dynamics principles in their design and develop structures with low resistance and high heat dissipation efficiency, such as optimized fin arrangement and microchannel design, to reduce the energy consumption required for cooling.

3. Intelligence and automation

The radiator manufacturer has introduced intelligent technology, such as integrated temperature sensors and intelligent control systems, which enable the radiator to automatically adjust the cooling mode according to the actual heat load, achieving dynamic thermal management. The use of automated production lines has also improved production efficiency and reduced human errors.

4. Lifecycle management

Manufacturers pay attention to the entire lifecycle of products, from design, manufacturing, use to recycling, to ensure minimal environmental impact at each stage. This includes providing detachable and upgradable designs for easy maintenance and refurbishment, as well as developing recycling plans to promote resource recycling.

5. Research and Innovation

Continuous R&D investment enables manufacturers to develop new materials, processes, and technologies, such as graphene based composite materials and advanced heat pipe technology. These innovations not only improve heat dissipation performance, but also promote the realization of green manufacturing.

6. Cooperation and partnership

Establish cooperative relationships with research institutions, universities, and other enterprises to share research results and jointly promote the development of green manufacturing and intelligent heat dissipation technology.

Through the above strategies, radiator manufacturers not only respond to industry trends, but also enhance their market competitiveness, laying a solid foundation for sustainable development and intelligent future.

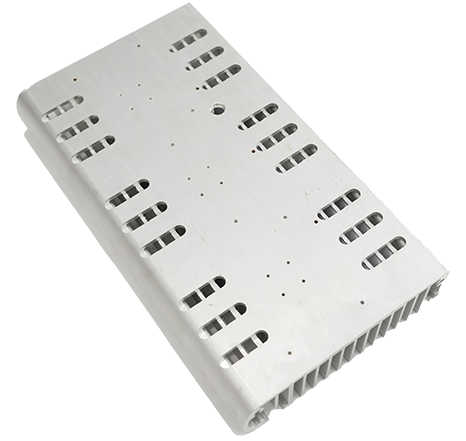

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network