Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 14:56:31

Visit:

The uniqueness of radiator manufacturers in design and manufacturing processes is usually reflected in multiple aspects such as material selection, structural innovation, manufacturing technology, and quality control, to ensure that the product achieves the best balance between performance, reliability, and cost-effectiveness. Here are a few key unique features:

1. Materials Science and Alloy Development

Heat sink manufacturers focus on the research and application of high-performance alloy materials, such as high thermal conductivity aluminum alloys, copper alloys, and even graphene composite materials, to improve thermal conductivity efficiency and corrosion resistance.

2. Structural optimization and innovation

Manufacturers will use principles of fluid mechanics and thermodynamics to design structures with high heat dissipation efficiency, such as microchannels, high-density fins, heat pipes, and composite heat sinks, which can increase heat dissipation area and improve heat flux distribution.

3. Manufacturing Technology

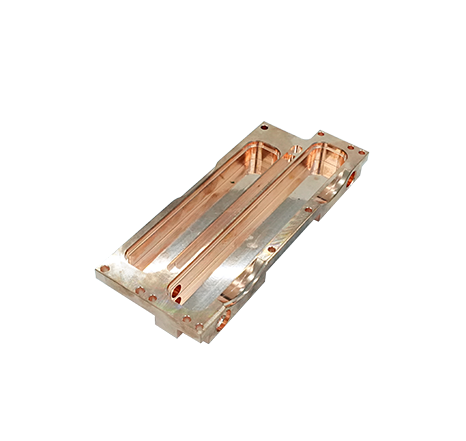

Adopting precision casting, extrusion molding, cold forging, CNC machining, laser cutting, and welding technologies to ensure the accuracy and consistency of the heat sink. For example, cold forging technology can improve the density of materials, reduce internal defects, and thus enhance thermal conductivity; CNC machining can achieve accurate manufacturing of complex shapes.

4. Intelligence and integration

Integrate sensors and control components into the heat sink design to provide intelligent temperature control functionality. Through IoT technology, heat sinks can be remotely monitored and adjusted to adapt to different working environments and thermal loads.

5. Quality Control and Testing

A strict quality management system, including material inspection, process monitoring, and finished product testing, ensures that each radiator meets high standards of performance and reliability requirements. This may involve thermal performance testing, pressure testing, vibration testing, and lifespan testing, among others.

6. Customization and flexibility

We provide highly customized services, designing and manufacturing heat sinks according to customers' specific needs, which can meet personalized requirements in terms of shape, size, and thermal performance parameters.

7. Green Manufacturing and Sustainability

Pay attention to environmental protection and sustainability, use green materials, optimize manufacturing processes to reduce energy consumption and waste generation, while ensuring that products are easy to recycle and reuse.

8. Data driven optimization

By utilizing big data and artificial intelligence technology for performance prediction and optimization, simulation and analysis tools can be used to predict the performance of heat sinks during the design phase, thereby reducing the number of iterations and accelerating product launch speed.

9. Patent Protection and Intellectual Property

The manufacturer has multiple patents related to the design and manufacturing of heat sinks, and these proprietary technologies are the core of its competitive advantage, ensuring the uniqueness and market position of the product.

In summary, the unique features of radiator manufacturers in design and manufacturing processes reflect their deep understanding and continuous innovation in materials, structure, technology, quality, and environmental protection, aiming to provide high-performance, efficient, and highly reliable heat dissipation solutions.

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network