Dongguan dry Xing Yuan hardware products Co., LTD

Phone: 13723735921

Address: No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

E-Mail: qxywj@qxyboom.com

Website: www.dgqxy.cn

2024-09-19 14:25:37

Visit:

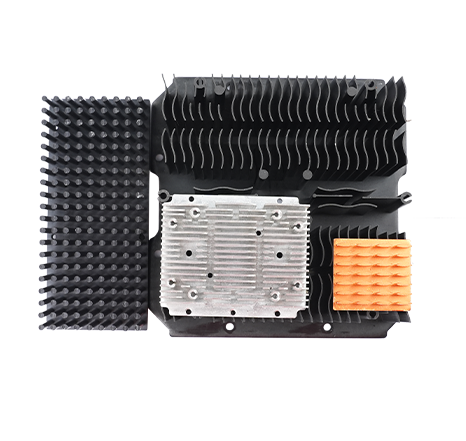

The material selection for cold forging heat sinks mainly focuses on metals and their alloys with good thermal conductivity and plastic deformation ability, to ensure effective heat conduction and withstand necessary plastic deformation without fracture during the cold forging process. Here are some commonly used material options:

1. Aluminum and aluminum alloys

Aluminum is one of the most commonly used materials in cold forging heat sinks because it has high thermal conductivity, good plasticity, and low density, making the processed heat sink lightweight and highly efficient in heat dissipation. Common aluminum alloys include:

AL1070: With a purity of up to 99.7% and a thermal conductivity of approximately 226W/m · K, it is an ideal cold forging material.

AL6063: A commonly used architectural aluminum profile that, after T5 heat treatment, has good thermal conductivity and mechanical strength.

AL1xxx series: These are pure aluminum or nearly pure aluminum alloys with good thermal conductivity and processability.

AL3xxx series: alloys containing manganese elements, with good corrosion resistance and processing performance.

2. Copper and copper alloys

Copper has a higher thermal conductivity than aluminum and is another excellent heat dissipation material. However, the high cost and density of copper may limit its use in certain applications. Copper alloys such as brass and bronze can also provide good thermal conductivity, while improving mechanical strength and corrosion resistance.

3. Other alloys

In addition to aluminum and copper, there are other metals and alloys that may be used for cold forged heat sinks for special applications, such as:

Titanium and titanium alloys: In applications that require high strength and lightweight, such as the aerospace industry, titanium alloys are the ideal choice.

Stainless steel: In environments that require corrosion resistance and high strength, stainless steel can be used as a cold forging material.

4. Composite materials

In some high-quality applications, composite materials may be used to achieve higher performance, such as combining copper sheets with aluminum materials to utilize the high thermal conductivity of copper and the lightweight and good processability of aluminum.

When choosing materials for cold forging radiators, factors such as cost, processing difficulty, weight limitations, environmental adaptability (such as corrosiveness), and specific requirements of the target application also need to be considered. For example, in electronic devices, lightweight and cost-effectiveness may be prioritized factors, while in aerospace and military applications, material strength and reliability are more critical.

In short, the material selection of cold forged heat sinks is a process that comprehensively considers thermal performance, mechanical performance, processing characteristics, and application requirements. Manufacturers need to determine the appropriate material based on specific application scenarios.

Focus on cold forging radiator, cold forging parts, cold forging IGBT copper and aluminum cooling module, super power radiator and other products.

+86-0769-33287786

13723735921

No. 462 Houda Road, Dalingshan Section, Dalingshan Town, Dongguan City

Copyright: Dongguan dry Xing Yuan hardware products Co., LTD

Service support: Huashang Network